Iintlobo ngeentlobo zezixhobo zekhaya, kwimizi-mvelisoii-frequency transformers, nokuba baqulunqa i-winding yabo, okanye balungise i-transformer etshisiweyo, babandakanyeka kwinxalenye yokubala okulula, iincwadi zezifundo kwi-formula, nangona zingqongqo, kodwa ukusetyenziswa okusebenzayo kobunzima, akulula kakhulu.Eli nqaku lazisa ukubalwa kwe-transformer ebonakalayo yefomula yobungqina.

1. Ukukhetha okungundoqo kwentsimbi

Ngokwamandla abo kufuneka bakhethe isiseko esilungileyo linyathelo lokuqala ekujikeni i-transformer. Ukuba i-iron core (i-silicon iron sheet) ukhetho lukhulu kakhulu, luya kukhokelela ekwandeni kobukhulu be-transformer, iindleko eziphezulu, kodwa intsimbi yentsimbi incinci kakhulu, iya kwandisa ilahleko ye-transformer, ngelixa amandla ukuthwala umthwalo uba lihlwempu.

Ukuze uqonde ubungakanani core yentsimbi, into yokuqala ukubala eyona ukusetyenziswa amandla isiguquli yesibini, nto leyo ilingana isiguquli sombane yesibini magingxigingxi, isixa imveliso umthwalo langoku. Ukuba i-full-wave rectifier transformer, kufuneka ibalwe njenge-1/2 ye-voltage yesibini ye-transformer. Ukusetyenziswa kwamandla okujika okwesibini ukujoyina i-transformer ngokwayo ilahleko yamandla, oko kukuthi, i-transformer yokuqala yamandla abonakalayo.

Amandla okuqukumbela jikelele esibini kwi-10w engaphantsi kwe-transformer, ilahleko yayo yokusetyenziswa kwamandla esibini inokuya kuthi ga kwi-30 ~ 50% yowona setyenziso lwamandla, ukusebenza kakuhle kwayo yi-50 ~ 70% kuphela. Amandla okuvala asezantsi kwi-30 w ngaphantsi kwelahleko emalunga nama-20 ~ 30%, 50 w ngaphantsi kwelahleko emalunga ne-15 ~ 20%, 100 w ngaphantsi kwelahleko emalunga ne-10 ~ 15%, 100 w ngaphezu kwelahleko emalunga ne-10% engezantsi, okungasentla. ilahleko iparameter imalunga ne-transformer yodidi lweplagi eqhelekileyo. Ukuba umyalelo we-R-type transformer, i-c-type transformer kunye ne-toroidal transformer ilandelwa, i-parameter yokulahlekelwa iyancipha ngokuphindaphindiweyo.

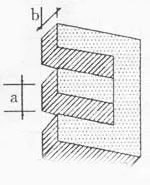

Ngokusekelwe kumandla eprayimari ewonke ye-transformer ebalwa ngaphezu kwengundoqo inokukhethwa. Indawo engundoqo yentsimbi S = i-axb (cm2). Njengoko kubonisiwe kumfanekiso oqhotyoshelweyo. Amandla abonakalayo aguqulayo kunye nobudlelwane phakathi kwe-s nale fomula yobungqina ilandelayo: s = K √ P1

I-P1 ye-transformer ephambili iyonke amandla abonakalayo, iyunithi: i-VA (i-volt-ampere), i-s kufuneka ikhethwe indawo engundoqo ye-cross-sectional, i-K yi-coefficient, kunye nobukhulu be-transformer Pl ukhetho oluhlukeneyo lwamaxabiso ahlukeneyo. Kwangaxeshanye, kuthathelwa ingqalelo i-silicon sheet sheet phakathi kwepeyinti yokugquma, isiphumo somsantsa, ubudlelwane be-K kunye ne-P1 bu:

P1 K ixabiso

10VA 2~2.2

50VA ngaphantsi kwe-2 ~ 1.5

lOOVA ngaphantsi kwe-1.5 ~ 1.4

2. Ukubalwa kojiko ngevolthi nganye

Emva kokukhetha i-core s. Emva koko unqume inani lokujika kwi-volt nganye, ukwenzela ukuba i-transformer ibe nomoya wokuvuselela ngokufanelekileyo. Ifomyula esetyenziswa ngokuqhelekileyo: N = (40 ~ 55)/S, N linani lokujika ngevolthi nganye.

Ngokomgangatho owahlukileyo we-silicon yentsimbi yokukhetha i-coefficient ye-40 ~ 55. ngaphezulu ephezulu ye-silicon yentsimbi, kunye neliso lokujonga umphezulu wezikali ze-crystallization. Kwaye i-brittle kakhulu, kuphela i-1 ukuya ku-2 amaxesha aqhekezayo, aphukile ngokungafaniyo, i-coefficient ithathwa njenge-40. umgca othe ngqo, i-coefficient ithathwa ngaphezu kwe-50.

Fumana inani lokujika ngevolthi nganye ephindaphindwe nge-220V engundoqo, iphindaphindwe ngenani leemfuno zombane wesibini ezizijiko zesibini zokujika. Ngenxa yokuba ucingo lunokuchasana, ukuhamba kwangoku ngokuhla kwamandla ombane, ukujika kwesibini kufuneka kwandiswe nge-5 ~ lO% (ngokokhetho lwangoku lomthwalo, umsinga unokunyuswa ngomlinganiselo omkhulu).

3. Ukukhethwa kwedayamitha yocingo

Ngokobungakanani bomthwalo ojikelezayo wangoku, khetha iidiameters ezahlukeneyo zocingo olunamele. Le fomula yobungqina ilandelayo inokusetyenziselwa ukufumanisa:

d=O.8√Mna.

Iyunithi: l – A. d (idayamitha yocingo) – mm.

4. Iindlela zokuvala kunye nezilumkiso

Ke, kule mihla, amandla e-insulation ocingo olwenziwe nge-enameled aphuculwe ngokwenene. Kubaabaguquli bamandla amancincimalunga ne-50W, sihlala sihamba kunye ne-skeleton yeplastiki ehlala idangatye kwaye sibeka ii-windings. Qiniseka nje ukuba usebenzisa i-enameled yocingo lwamandla aphezulu, kwaye xa uyisonga, gcina yonke into ifakwe umaleko ngomaleko-akukho zithuba ezinkulu zediagonal ezivunyelweyo! Oku kunceda ukuphepha ukonyusa umahluko wombane phakathi kweengcingo. Kwiziguquli ezingaphezulu kwe-50W, kuba kukho ukujika okumbalwa ngevolthi nganye, umahluko wombane phakathi kweengcingo uba phezulu. Kungcono ukubeka phantsi iphepha le-insulating (elifana ne-0.05mm ye-cable sheet engqindilili okanye i-kraft paper) kumaleko ngamnye njengoko ulisonga.

Ngokuqinisekileyo ufuna ukuthintela naziphi na iileya eziphezulu ukuba zityibilike zibe ngaphantsi! Ukwaleka phakathi kwee-windings kufuneka kuxhomekeke kubungakanani bombane osebenza nawo. Phakathi kwamanqanaba eprayimari, jolise ubuncinci kwimigangatho emine yephepha lentambo ye-0.1mm-yeqa usebenzisa i-tape yokunamathela apha! Ukuba i-transformer yakho encinci inamaqela angaphezu kwamabini e-windings yesibini ebekwe kunye, qiniseka ukuba wongeza iileya ezimbini zokugquma kwamaphepha entambo phakathi kweqela ngalinye. Kwaye ukuba le transformer iya kwi audio okanye audiovisual gear? Ungalibali ukubandakanya i-electrostatic shielding padding kwezo useto lwe-multi-layer. Emva kokuba uyenzile yonke loo nto ijikelezayo, nikela ingqalelo xa ufaka i-silicon sheet sheets-kufuneka ilingane kakuhle ukuze ungafumani ingxolo ye-electromagnetic ephazamisa izinto.

Nokuba i-E-shaped kabini okanye i-EI-shaped sheets, kufuneka ihlanganiswe ngokuqinileyo ngaphandle kwezithuba; ukuwawela nawo kunokunceda! Xa ufaka ezo ziqwenga ezimbalwa zokugqibela (malunga nezine okanye ezintlanu), yenze ukusuka kwiziko ukuze ungonakalisi naziphi na iinyanda zocingo endleleni. Emva koko masiyomise kwaye siyithi nkxu kwipeyinti emva koko! Kwiziguquli ezingaphantsi kwe-50W, ungasebenzisa indlela yokumisa i-endothermic: i-short-circuit yonke i-windings yesibini kuqala uze udibanise ibhalbhu yokukhanya (60 ~ 100W / 220V) ngoluhlu olunamandla ombane ukuze izifudumeze ngokuzenzekelayo.Ibhalbhu enkulu, ukuphakama kweqondo lokushisa, kodwa kwimeko evaliweyo, ukwenzela ukuba iqondo lokushisa lingaphantsi kwama-80 degrees likhuselekile.

Ixesha lokuposa: Sep-25-2024